Lean methodology, lean production or just 'lean' offers a new approach to workflow management that focuses on eliminating waste and optimising resources. Lean is something we talk about quite a lot here at Deep Blue Sky and in this post we're going to explain what lean means and how you can use it to improve your processes.

What exactly is 'lean'?

Great question!

Lean is a systematic method used to minimise waste within a process. The way we used lean philosophy today is derived largely from the Toyota Production System. This system was found to reduce the time it takes to satisfy customers by more than 30% by doing only what is necessary and pivoting quickly as a result of validated learning.

W. Edwards Deming

How does it differ from other management methods like 'waterfall' or 'agile'?

Integrate frequent feedback from your target audience.

Waterfall project management works really well as long as both the solution and the problem are already well defined. Since this is so rare in innovative organisations, you might look to agile methodology for answers on how to plan in unknown changes to your project plan.

Agile project management is designed for situations where the problem is well defined but the solution is unknown, so by building iteratively you can increase the likelihood that the project is a success.

Lean principles are applied to the full customer lifecycle and are focused on creating as much value as possible to the end user by validating learning and gathering feedback as frequently as possible. Lean principles work really well in combination with agile development sprints.

What's the value of using lean production methodology in your company?

Reduce waste and create time for innovation.

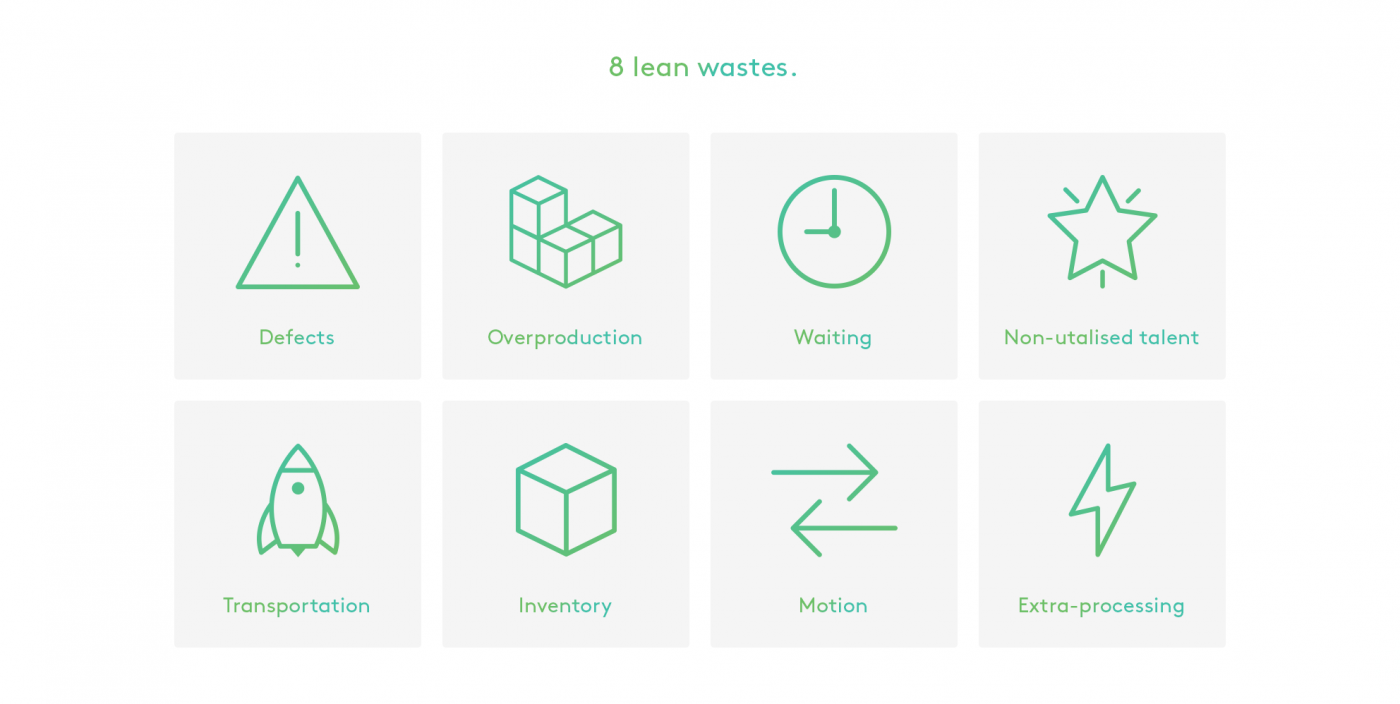

Traditionally lean identifies 7 key types of waste, often referred to as 'Seven Deadly Wastes'. But how do you define waste? Put simply, waste is anything and everything that does not add value from the perspective of your own customer.

As we've explored lean methodology in more depth at Deep Blue Sky, we've found there are 8 key types of waste in total. Check out the diagram below for the full list. By identifying where each of these are happening across your production lifecycle you can start to iteratively improve productivity.

How can you get started with lean?

There are a ton of great resources out there that breakdown how to modify lean methodologies to suit your business workflow. Here's a short list of resources we recommend checking out before switching:

Books

- The Lean Start Up by Eric Ries

- The Machine That Changed The World by James Womack, Daniel Jones, and Daniel Roos

Videos

- Lean Applied to Us by Bill Peterson at TEDxKnoxville

- "The Lean Startup" Talk at Google

Alternatively you can pop in to our office in Bath for a coffee anytime to chat more about the power of lean thinking and how you can use it to drive efficiency in your business.

Write a comment.